Flowmeters

For e.g. Crude oil/Fossil Fuel which we get naturally underneath the earth, created by nature in millions of years is not useful naturally, it is refined, heated, chemically reacted to produce useful products like Gasoline(Petrol/Diesel/LNG), Naphtha, Kerosene, Asphalt etc.

Operation to generate useful products from Crude oil is called Process. Process means organizing various activities like, refining, heating, cooling, chemical reaction in a controlled manner to produce useful products out of raw material.

Above pic shows a typical Oil refinery, where crude oil is converted into gasoline & other useful products.

These refineries & other chemical plants are fully automatic & the process of huge plants like this are controlled automatically with Operator to feed input values & required output values to the Logical controller i.e. Distributed Control Systems (DCS), Programmable Logic Controller (PLC).

These plants are designed to automatically manage the Emergency shutdown in case of any mishaps, saving lives & assets.

Flowmeters: One of variable to control the process is Flow, in order to take proper decision by operator/logic, they must know exact value of the flow inside the pipeline. i.e. in order to avoid overflow/over pressurization of tank/ pipeline, flow inside the pipeline must be known, so that some automatic Valve can be opened to avoid over pressurization & thus to prevent bursting of pipeline or tank.

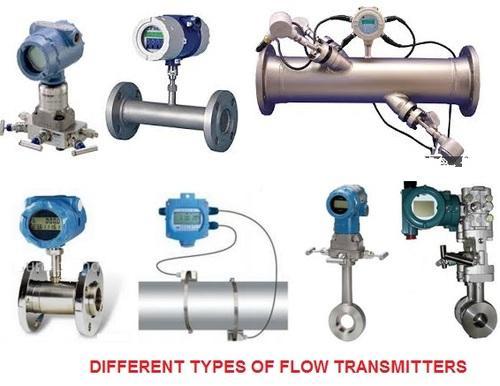

Various flow meters as shown in the pic above are installed inline with pipeline, to measure flow of the fluid. These flow meters have different working principles.

Types of Flow meters : 1. Restriction Orifice, 2. Flow nozzle, 3. Ventury tube, 4. Electro-magnetic flow meter, 5. Ultra Sonic flow meter, 6. Turbine Flow meter, 7. Vortex flow meter, 8. Coriollis mass flow meter, 9. Variable Area flow meter(Rotameter)

As shown in the picture, Restriction orifice plates are obstruction in the pipeline to create pressure difference between inlet and outlet of this plates. As per #Bernoulli’s equation, flow of the fluid is proportional to difference in the pressure at any point in the pipeline.

Types of Orifice plates: 1. Concentric, 2. Eccentric 3. Segmental

Concentric Orifice has hole in the center, eccentric has hole off center & segmental has a segment cut from the plate.

2. Flow nozzle: Flow nozzles are another way of creating pressure difference at two points in the pipeline.

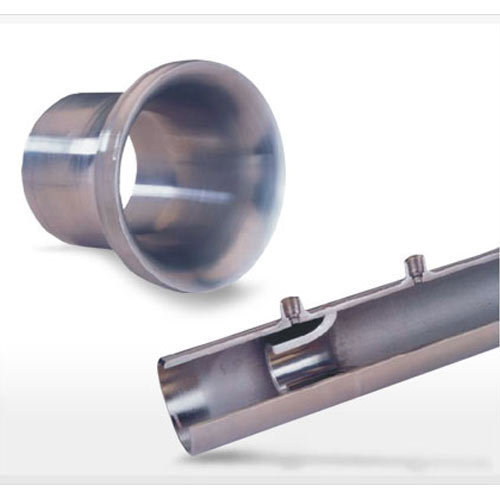

3. Ventury Tube: Ventury tube is narrow tube as shown in the pic below, coz of difference in the pipe diameter at different points, there will be a pressure difference between two taps, which can be later used to measure pressure difference & hence flow rate of the fluid.

0

0